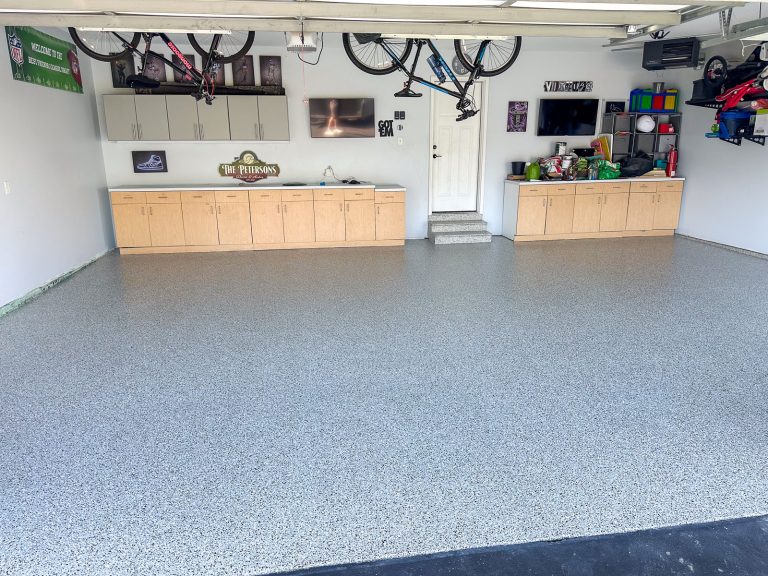

Homeowner Problem → Slab Lab Solution

Your current/future garage floor problems:

Pitting and spalling from salt

Cracks spreading each winter

Dusty, dull concrete that makes your garage feel dirty

Old coatings or DIY kits peeling off

Oil stains you can’t scrub out

What Slab Lab delivers:

A completely restored & sealed surface that looks brand new

Industrial-grade coatings that won’t peel

A brighter, cleaner, dust-free garage

Long-term protection against salt, chemicals, moisture, and hot tires

A finish that actually adds usable space to your hom

Why Minnesota Homeowners Choose Slab Lab

At Slab Lab, Minnesota homeowners choose us because we deliver inspector-level concrete preparation and repair that most competitors skip entirely. We fix pitting, cracking, and spalling the right way before any coating goes down, ensuring long-term adhesion and a floor that lasts through Minnesota’s harsh freeze–thaw cycles. Our premium polyurea and polyaspartic garage floor coating systems outperform cheap DIY kits and big-box alternatives, giving you a durable, beautiful finish in as little as 1–2 days. With dozens of decorative flake blends, custom finishes, and high-performance coating options, we create floors tailored to your home—not cookie-cutter results. We don’t aim to be the biggest concrete coating company in Minnesota; we aim to be the best, delivering unmatched quality, honest craftsmanship, and flooring systems built to stand the test of time.

What Customers Have to Say About Slab Lab Coatings

Slab Lab Coating Process

Diamond Grind

We grind, repair, and vacuum the surface to ensure maximum adhesion.

Repair

We fix cracks or chips in the concrete for a smooth, seamless surface.

Coat

We apply a high-solids self-priming epoxy or polyaspartic base coat.

Flake

We spread polymer flakes evenly for uniform texture and color.

Scrape

Excess flakes are removed to create a level surface, prepping for final sealing.

Seal

A scratch-resistant, UV-stable polyaspartic topcoat is applied and hardens in 6-8 hours.

The Slab Lab Difference

| Category | Polyurea / Polyaspartic System (What Slab Lab Uses) | Standard Epoxy Floors (What Most Competitors Use) |

|---|---|---|

| Strength & Flexibility | Highly flexible—expands and contracts with Minnesota temperature swings. Much stronger bond to concrete, prevents cracking, peeling, and delamination. | Rigid and brittle. Cannot flex with concrete movement, leading to peeling, cracking, and hot-tire pickup. |

| Durability | Industrial-grade – 4X more durable & designed for garages, basements, and outdoor areas. Withstands heavy traffic, impacts, dropped tools, and daily use. | More prone to scratching, chipping, hot tire lifting, and surface wear—especially in cold climates. |

| Chemical Resistance | Exceptional resistance to road salt, gasoline, oil, brake fluid, household chemicals, and deicers. Ideal for Minnesota winters. | Chemical staining and damage are common. Road salt, oil, and deicers can permanently mark or compromise epoxy. |

| UV Stability | 100% UV stable—won’t yellow, fade, or discolor outdoors or near windows. Perfect for patios and sunny garages. | Yellows and fades over time, especially in sun-exposed areas. Not recommended for outdoor concrete. |

| Cure Time | Fast cure—walkable within hours, ready in 1 day, fully usable in 24–48 hours. | Slow cure—can take 48–72 hours or longer. Sensitive to humidity and temperature during installation. |

| Lifespan | 15–20+ years with proper maintenance. Engineered for long-term performance in extreme climates. | 3–7 years before peeling, cracking, or wearing out. Shorter lifespan in cold-weather states. |

| Bond to Concrete | Penetrates deeper into the concrete for a permanent mechanical bond. Resists moisture pressure and salt intrusion. | Sits more on the surface with a weaker bond. More likely to fail over time, especially on older or porous slabs. |

| Appearance & Finish | Rich, premium finish with high clarity. Available in dozens of flake blends, colors, and custom textures. Looks like a showroom. | Glossy but less refined. Limited style options. Can develop dull spots or wear patterns. |

| Feel (Texture & Comfort) | Slip-resistant options available. Slightly warmer underfoot. Seamless and smooth but safe to walk on—ideal for garages and basements. | Can be slick when wet. Tends to feel harder, colder, and less comfortable. |

| Maintenance | Extremely low-maintenance. Just sweep and mop. Resistant to dust and stains. | Requires regular cleaning and recoating. Prone to staining and dulling. |

| Outdoor Use | Excellent—designed for patios, porches, pool decks, and sun-exposed concrete. | Not recommended outdoors. UV exposure causes yellowing and peeling. |

| Cost vs. Value | Slightly higher initial cost but dramatically lower lifetime cost due to longevity and performance. | Lower upfront cost, but higher long-term cost due to early failure and replacement. |

Concrete Repair & Prep

Every garage floor is mechanically diamond-ground to open the pores of the concrete and create a permanent bond.

We also repair:

- Cracks

- Pitting

- Spalling

- Uneven or damaged areas

This ensures the coating adheres correctly and lasts for years.